With targets to get more car stock available for sale and to sell more of that stock, ensuring the Inventory Operations team had everything they need was a key driver of this piece of work.

On this project, my aim was to understand the full end to end of the Inventory Operations service at cinch and to identify where pain exists or has built up since launch, then identify where opportunities are to improve efficiencies to provide better business outcomes.

Discovery

In order to achieve the desired outcomes and goals, the first activity was to have a session with the Product Owner to understand aims, scope and outcomes and discuss how we could achieve this. We agreed to do in-person mapping workshop with the team involved in managing inventory, to digest the full end to end process and layer in those areas of pain or time spent that was hindering the team reaching their targets.

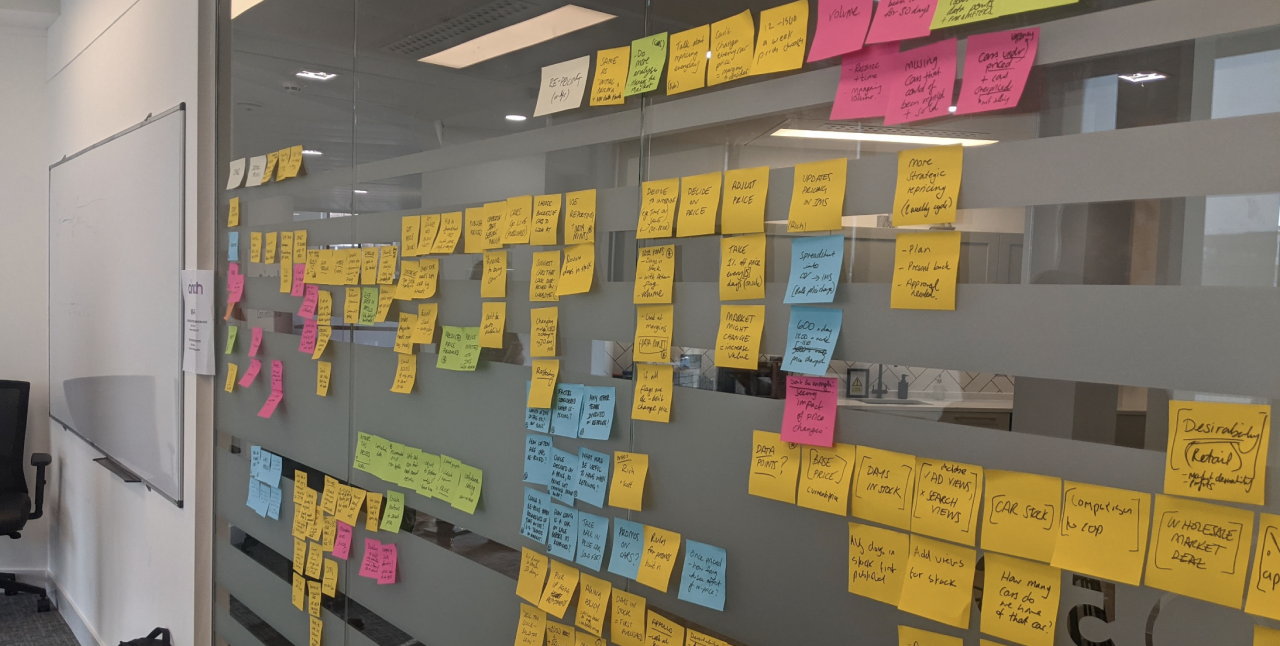

I helped plan and facilitate multiple workshops with the Inventory team in Wolverhampton and Manchester where we mapped out processes, people, pains and systems across the end to end of ‘getting cars on sale’ and ‘managing cars in life.’ In order to get the most out of the session, I broke the full journey into sections so we could tackle each phase of the journey in bite-size chunks.

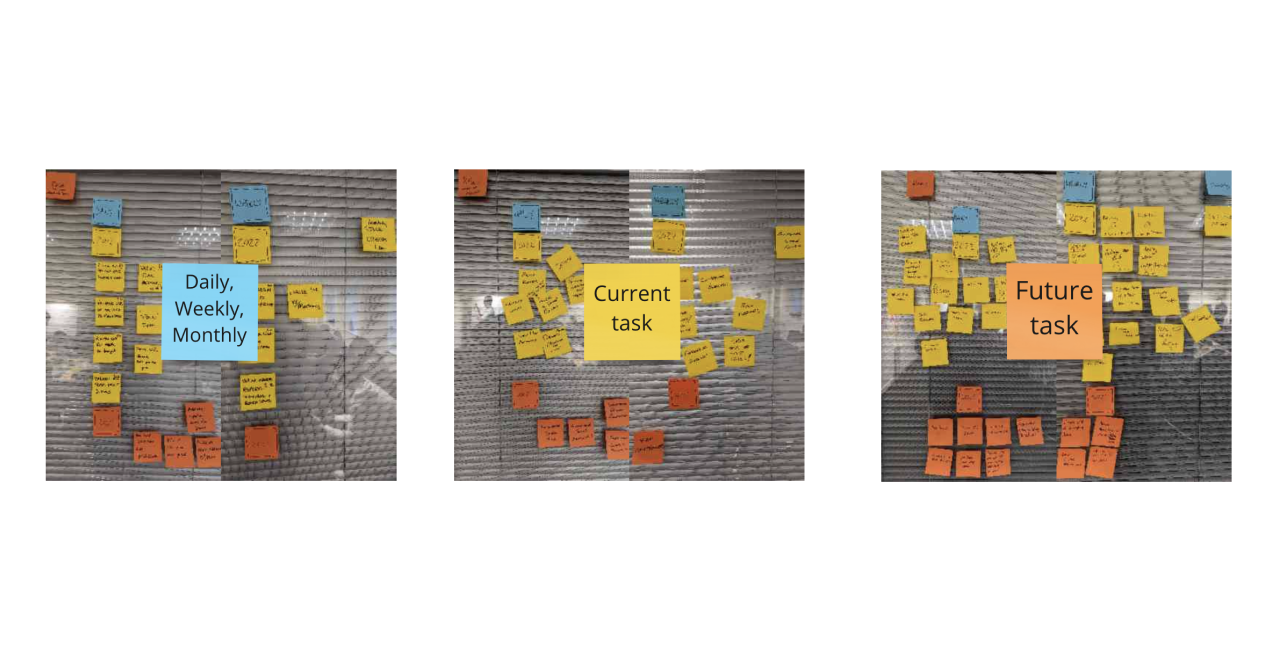

We also ran a workshop on understanding daily, weekly and monthly tasks each team member did. This was to help gain more context around how often tasks were taking place and how long it took to complete them. For example, a task of gathering information may only take a couple of minutes, but for multiple cars this could take a full day.

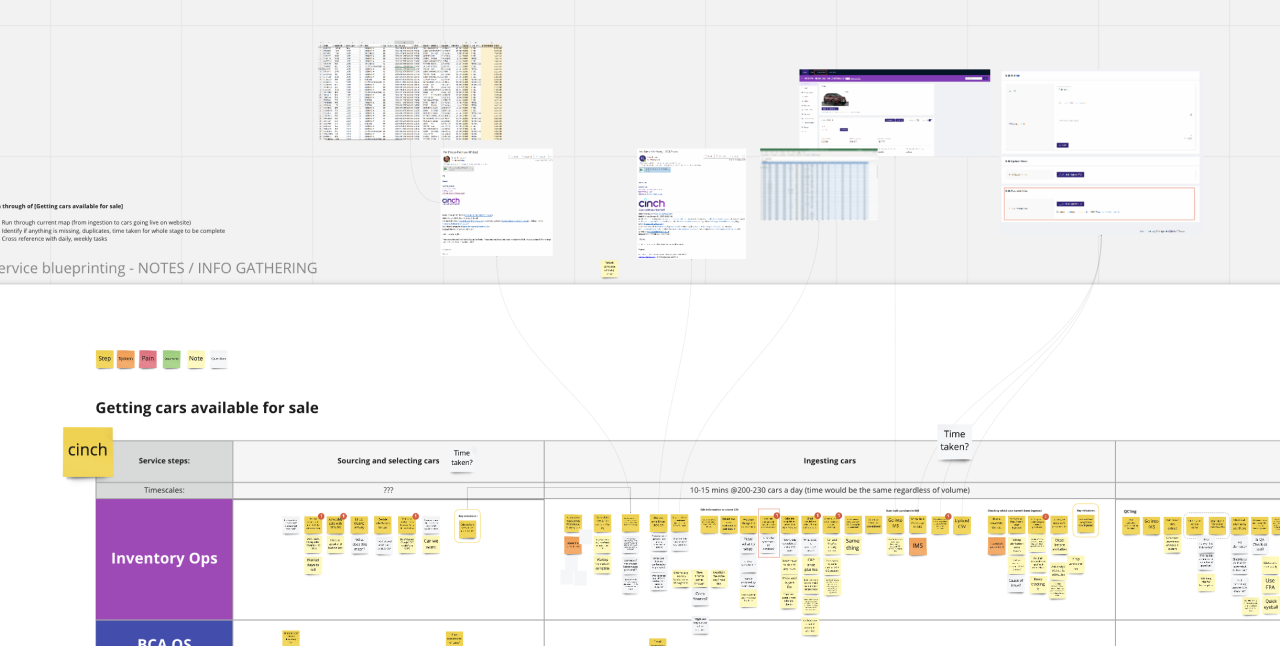

Off the back of the session, I tidied up all insights gained and formed an initial service blueprint. This highlighted some gaps in processes and triggered extra questions for the team. I therefore ran some mini sessions with key team members to run through those questions and plug gaps of information.

Defining challenges and opportunities

Piecing all the sections of the service together into the service blueprint enabled me to start to understand all the areas of opportunity. I started to look at the all the pain points discovered in the workshops across the end to end and then grouped them all together to synthesis and find key themes.

High level themes uncovered lots of manual processes which were time consuming for the team and also increased the risk of error, both of which delayed the time it took to get cars available for sale. Time spent on manual tasks also meant the team wasn't able to focus on other areas of managing stock including helping to drive sales.

Collaborating with the Product Owner, I gathered all the key pain points which started to form a backlog of opportunities to work from to drive improvement. We played the themes back to the team and to help prioritise where to start first, we asked the team to vote individually on which pain points they thought would have the most impact to be tackled.

Design

Through looking at all the pain and time to task across the service, there were some clear opportunities to help improve the inventory service reduce the time to get cars on sale. Working collaboratively with the team, we came up with high level ideas that could improve the service.

It became clear that many areas of the service could be automated, but still enable issues to be flagged for human intervention. Other areas involved using data to help develop a smart pricing tools, that would gather intel from multiple sources (that are currently sourced manually) to provide a ‘recommended price’ for the team to review.

Outcomes

This work has enabled a prioritised backlog opportunities to solve for Q1 and beyond to be generated to help the team achieve targets of getting more and more cars on sale and sold.

"What a fantastic session, big shout out to the Inventory Operations team for spending the day with us mapping out 'A day in the life' of managing inventory, whereby we highlighted key pain points within their process. Solving these problems will be pivotal in enabling scale within that space. Big thank you to Service Design for leading the session" - cinch Product

"Great work in pulling together the inventory mapping session. Exciting times ahead to make a difference" - cinch Product

"Great work on the inventory journey, really helping to find those opportunities for improvements" - cinch Design

"Fab workshop with inventory and pricing, and run through of the Inventory Ops processes...so good in fact, I'm going to steal the format!" - cinch Design